| X Axis Travel: | 1200mm | Y Axis Travel: | 600mm |

|---|---|---|---|

| Z Axis Travel: | 600mm | X/Y/Z Axis Rapid Feed: | 30/30/30 M/min |

| Cutting Feed: | 10 M/min | Spindle Speed: | 8000rpm |

| Table Size: | 1200*600mm | Spindle Taper: | BT50 |

Three axis ball linear wayCNC Machine Center VMC1160L3

VMC-1160L3 with optimizing machine body structure design has advantages in processing efficiency, processing precision and smooth finish of mould curved surface processing ,can be widely applied to 3C product ,Automatic special parts ,electronic, mechanical, automobile, precision medicine and other field of product processing.

VMC-1160L3 with optimizing machine body structure design has advantages in processing efficiency, processing precision and smooth finish of mould curved surface processing ,can be widely applied to 3C product ,Automatic special parts ,electronic, mechanical, automobile, precision medicine and other field of product processing.

1. The base, the workbench, the column, the beam, the sliding seat and the ram are all made of high-quality resin sand. High-strength,high-quality cast iron, with a complete heat treatment process to eliminate residual stress and arrange enough reinforcement. Thisstructureensures sufficient strength, rigidity and high stability of the machine. 2. X/Y axis adopts ball linear way with strong rigidity and good dynamic precision. 3. Three-axis transmission adopts Taiwan brand large-diameter grinding double-nutball screw, which has compact structure, stable movement and high precision. 4. The high-rigid Taiwan brand spindle, which is lubricated with grease, can make the spindle bearing have constant and reliable lubrication, canrealizes long-term maintenance-free.

1. The base, the workbench, the column, the beam, the sliding seat and the ram are all made of high-quality resin sand. High-strength,high-quality cast iron, with a complete heat treatment process to eliminate residual stress and arrange enough reinforcement. Thisstructureensures sufficient strength, rigidity and high stability of the machine. 2. X/Y axis adopts ball linear way with strong rigidity and good dynamic precision. 3. Three-axis transmission adopts Taiwan brand large-diameter grinding double-nutball screw, which has compact structure, stable movement and high precision. 4. The high-rigid Taiwan brand spindle, which is lubricated with grease, can make the spindle bearing have constant and reliable lubrication, canrealizes long-term maintenance-free.

1. Fanuc MF(5) Controller system 2. 8000Rpm spindle 3. Full enclosed cover 4.Spindle encoder position system 5. Three axis inner encoder feedback system 6. Auto lubrication system 7. Pneumatic system 8. RS 232 Interface 9. Operation unit 10. Working light 11. Tool and tool box

1. Fanuc MF(5) Controller system 2. 8000Rpm spindle 3. Full enclosed cover 4.Spindle encoder position system 5. Three axis inner encoder feedback system 6. Auto lubrication system 7. Pneumatic system 8. RS 232 Interface 9. Operation unit 10. Working light 11. Tool and tool box  1. M80A Mitsubishi controller system 2. Spindle oil coolant 3. Heat exchanger 4. Umbrella type tool magazine 5. Arm type tool magazine 6. Screw type auto conveyor 7. Chain type tool magazine 8. 4 Axis rotary table 9. Ring spray spindle

1. M80A Mitsubishi controller system 2. Spindle oil coolant 3. Heat exchanger 4. Umbrella type tool magazine 5. Arm type tool magazine 6. Screw type auto conveyor 7. Chain type tool magazine 8. 4 Axis rotary table 9. Ring spray spindle

VMC-1160L3 with optimizing machine body structure design has advantages in processing efficiency, processing precision and smooth finish of mould curved surface processing ,can be widely applied to 3C product ,Automatic special parts ,electronic, mechanical, automobile, precision medicine and other field of product processing.

VMC-1160L3 with optimizing machine body structure design has advantages in processing efficiency, processing precision and smooth finish of mould curved surface processing ,can be widely applied to 3C product ,Automatic special parts ,electronic, mechanical, automobile, precision medicine and other field of product processing.

1. The base, the workbench, the column, the beam, the sliding seat and the ram are all made of high-quality resin sand. High-strength,high-quality cast iron, with a complete heat treatment process to eliminate residual stress and arrange enough reinforcement. Thisstructureensures sufficient strength, rigidity and high stability of the machine. 2. X/Y axis adopts ball linear way with strong rigidity and good dynamic precision. 3. Three-axis transmission adopts Taiwan brand large-diameter grinding double-nutball screw, which has compact structure, stable movement and high precision. 4. The high-rigid Taiwan brand spindle, which is lubricated with grease, can make the spindle bearing have constant and reliable lubrication, canrealizes long-term maintenance-free.

1. The base, the workbench, the column, the beam, the sliding seat and the ram are all made of high-quality resin sand. High-strength,high-quality cast iron, with a complete heat treatment process to eliminate residual stress and arrange enough reinforcement. Thisstructureensures sufficient strength, rigidity and high stability of the machine. 2. X/Y axis adopts ball linear way with strong rigidity and good dynamic precision. 3. Three-axis transmission adopts Taiwan brand large-diameter grinding double-nutball screw, which has compact structure, stable movement and high precision. 4. The high-rigid Taiwan brand spindle, which is lubricated with grease, can make the spindle bearing have constant and reliable lubrication, canrealizes long-term maintenance-free.

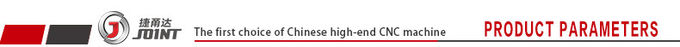

| Model | Unit | VMC-1160L3 | ||

| Travel | X axis | mm | 1100 | |

| Y axis | mm | 600 | ||

| Z axis | mm | 600 | ||

| Distance between spindle and table | mm | 100-700 | ||

| Working table | Table size | mm | 1200*600 | |

| Max. Load of table | Kg | 800 | ||

| T slot | Pcs-mm-mm | 5-18-100 | ||

| Positioning accuracy | X/Y/Z axis | mm | 0.008/0.008/0.008 | |

| Repeated positioning accuracy | X/Y/Z axis | mm | 0.006/0.006/0.006 | |

| Spindle | Spindle rotation speed | Rpm | 8000 | |

| Spindle taper | BT40 | |||

| Motor | KW | 11 | ||

| Diameter | mm | Φ150 | ||

| Rapid feed | X/Y/Z axis | m/min | 30/30/30 | |

| Cutting feed | X/Y/Z axis | m/min | 10 | |

| Tool magazine | Umbrella type | Size | Tools | 20 |

| Too changing time (T-T) | Sec | 8s | ||

| Max.tool weight | Kg | 15 | ||

| Max tool diameter (no tool adjacent) | mm | 150/180 | ||

| Arm type | Size | Tools | 24 | |

| Tool changing time (T-T) | sec | 4.5s | ||

| Max. diameter/ /length/weight of tool | mm | 110/200 | ||

| Max. tool weight | Kg | 15 | ||

| Net weight | Kg | 6500 | ||

| Dimension | mm | 3300*2050*2420 | ||

1. Fanuc MF(5) Controller system 2. 8000Rpm spindle 3. Full enclosed cover 4.Spindle encoder position system 5. Three axis inner encoder feedback system 6. Auto lubrication system 7. Pneumatic system 8. RS 232 Interface 9. Operation unit 10. Working light 11. Tool and tool box

1. Fanuc MF(5) Controller system 2. 8000Rpm spindle 3. Full enclosed cover 4.Spindle encoder position system 5. Three axis inner encoder feedback system 6. Auto lubrication system 7. Pneumatic system 8. RS 232 Interface 9. Operation unit 10. Working light 11. Tool and tool box  1. M80A Mitsubishi controller system 2. Spindle oil coolant 3. Heat exchanger 4. Umbrella type tool magazine 5. Arm type tool magazine 6. Screw type auto conveyor 7. Chain type tool magazine 8. 4 Axis rotary table 9. Ring spray spindle

1. M80A Mitsubishi controller system 2. Spindle oil coolant 3. Heat exchanger 4. Umbrella type tool magazine 5. Arm type tool magazine 6. Screw type auto conveyor 7. Chain type tool magazine 8. 4 Axis rotary table 9. Ring spray spindle