Rock drilling is an essential process that involves drilling into rocks and other solid surfaces to extract minerals or for construction purposes. It is a challenging task that requires specialized equipment such as rock bullets, drilling machines, and drilling tools to achieve optimum results. The depth of the drilling varies depending on the type of rock and the purpose of drilling. In this blog post, we will discuss rock drilling and its important components, including drilling depth, rock drilling equipment, and techniques.

Drilling Depth

Drilling depth is an important factor that determines the efficiency and success of rock drilling. It refers to the distance or length of the hole created by the drilling process. Different types of rocks require different drilling depths due to their varying hardness and strength. For example, softer rocks like limestone require shallower depths compared to harder rocks like granite. The drilling depth also depends on the purpose of drilling, whether for mining or for construction.

Rock Drilling Equipment

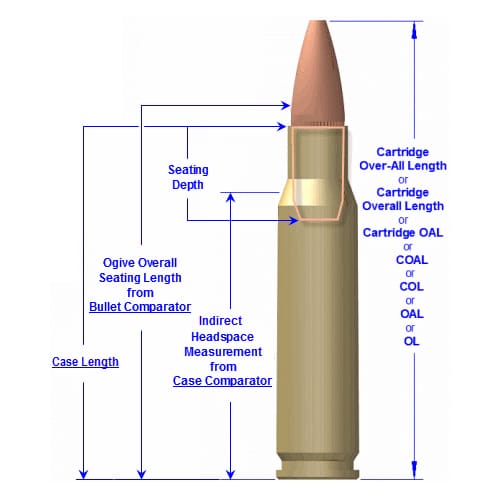

Rock drilling equipment is imperative in the drilling process. The equipment used should be high-quality and durable to withstand the harsh conditions encountered during drilling. A rock bullet is one of the essential drilling equipment necessary for rock drilling. It is a specialized drilling tool used to create holes in rocks or other solid surfaces. A typical rock bullet has an overall length of 1 meter and can drill up to a depth of 540 cm. It is made of robust and durable materials to withstand the pressure exerted during drilling.

Other equipment used in rock drilling include drilling machines and tools. The drilling machines vary in size and configuration, depending on the type of rock and the purpose of drilling. There are underground drilling machines that are specifically designed for drilling in narrow and confined spaces. The drilling tools include drilling bits, hammers, and drill rods, among others. The drilling tools are designed to withstand the pressure, friction, and temperature changes experienced during drilling.

Drilling Techniques

Rock drilling techniques vary depending on the geological characteristics of the rock and the purpose of drilling. One of the common drilling techniques is rotary drilling, which involves rotating a drill bit against the rock surface to create a hole. Another technique is percussion drilling, which uses a hammering motion to create a hole. In underground drilling, directional drilling is used to create a hole in a specific direction or angle. The drilling technique used should be precise, efficient, and safe to achieve the desired results.

Conclusion

Rock drilling is a complex process that requires specialized equipment and techniques to achieve optimum results. The depth of drilling is an important factor that determines the success of the drilling process. Rock drilling equipment such as rock bullets, drilling machines, and drilling tools are essential for the drilling process. The drilling techniques used depend on the geological characteristics of the rock and the purpose of drilling. With proper equipment and techniques, rock drilling can be a safe and effective process for mining and construction purposes.